Integrated TaN Resistors

|

ATP offers a wide variety of TaN sheet resistivities from 10–200 Ohms/square. Our standard and most cost effective sheet resistivities are 50, 75, and 100 Ohms/square. Resistor tolerances are available depending on material surface finishes and resistor design layout. Tolerances for thermal stabilization (heat treat) will be dependent upon the resistor values, resistor sizes, and number of resistors in the design. ATP does offer laser trimming to tolerances as low as ±0.5%, or ±0.25 Ohms, if required. Selective and Multiple TaN sheet ResistivitiesFor production efficiency, substrates with thin-film resistors are blanket-coated with Tantalum Nitride (Ta2N or TaN for brevity). Performance of some special circuit designs might be degraded by the presence of the TaN layer under transmission lines, edge-coupled filters or resonant stubs. ATP can provide circuits with TaN deposited only where it is needed for resistor formation. Additional processing steps are required for this selective TaN patterning. ATP offers the option of having multiple TaN sheet resistances in the same design. Please contact ATP Sales on your specific needs and we will review your design for compatibility. Keep in mind that the smaller the resistor, the higher the difficulty to achieve tighter tolerances due to the area and the size of the beam. A small area of trimming can change the resistor value dramatically. With laser trimming, additional tooling and time will be required. |

|

|||||||||||||||||||||||||||||

|

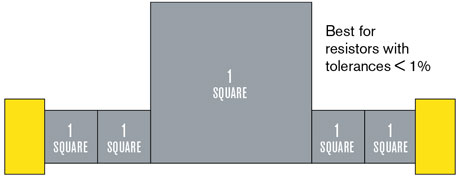

Basic Equation For Calculating ResistanceThe resistance of a specific resistor depends on its aspect ratio (the ratio of its length to width) expressed as a number of “squares” (note: the term “square” is dimensionless).

|

|||||||||||||||||||||||||||||

|

Resistor “length” is always the dimension of the resistor parallel to the current flow. |

|

|||||||||||||||||||||||||||||

|

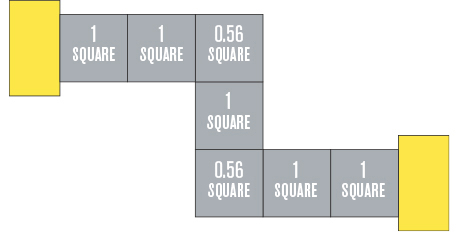

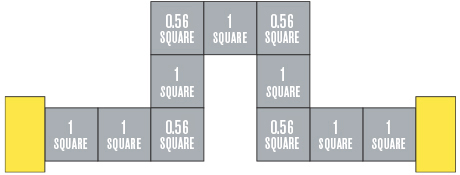

The resistor “square” in the corner area of a bent style resistor should be counted as 0.56 the value of the sheet resistance. |

|

|||||||||||||||||||||||||||||

Resistor Types |

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

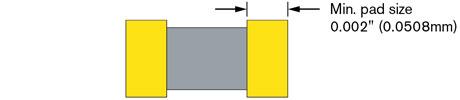

Square or Rectangular Configuration: The most common type of resistor. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

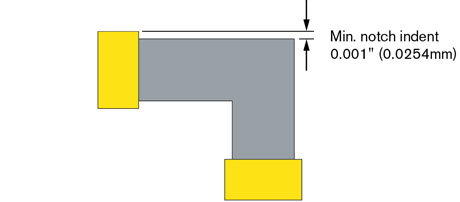

L or Bent Configuration: The resistor “square” in the corner area(s) of a bent style resistor (e.g. an “L” shape or serpentine design) should be counted as 0.56 the value of the sheet resistance. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

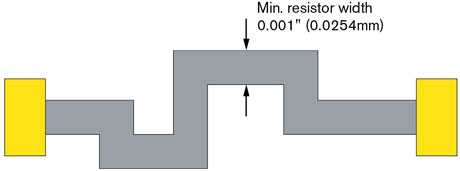

S Configuration: This type of resistor is also offered by ATP on some complex designs. Note that resistor tolerances may be difficult to achieve. The resistor can be “heat treated” on best effort. If “laser trimming” is required for tighter tolerances, the design may have to be adjusted. Contact ATP Sales for more information. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Serpentine Configuration: This resistor is typically used for high value resistors. The number of corners complicates calculation of the value. The resistor “square” in the corner areas of a serpentine style resistor should be counted as 0.56 the value of the sheet resistance. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Top-Hat (Lobe Type) Configuration: The advantage of a top-hat design is its wide trim range. Here we have a five square resistor. By trimming with a single plunge cut of the laser, a nine square resistor can be created. The resistance can be manipulated between these values by limiting the amount of trim. Resistors with a trimmable range of more than 3x the initial value can be created using this technique. Resistors of this type must be trimmed regardless of tolerance requirements. This type of design can also offer better tolerance accuracy down to ±0.5%. This design will require larger pad sizes. Recommend 0.003 or 0.0762mm as a minimum. |

|

|||||||||||||||||||||||||||||