Laser Resistor Trimming

|

With laser trimmed resistors ATP can achieve tolerance of ±0.5% depending on design and material. Polished material is recommended when tighter tolerances are needed. Most laser trim types can achieve the ±1.0% without difficulty as long as the TaN area is large enough. See Recommended Minimum Trimmable TaN Area chart. Below are listed all the different types of resistors that can achieve these types of tolerances. |

Laser beam spot trim typical size is 0.001" (0.0254mm). |

|||||||||||||||||||||||||||||

Laser Trim Types |

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

Plunge Cut: The most economical laser trim type. This is primarily due to the minimum amount of time required to trim the resistor with this technique. Overall tolerance accuracy can be less than the other methods. This method is recommended for DC applications. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

L Cut: This method offers increased tolerance accuracy over the Plunge Cut. Due to longer time required to perform this cut, it is slightly more expensive. This method is recommended for DC applications. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

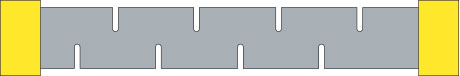

Serpentine Cut: This trim type allows wider final value flexibility than the Plunge or L Cut. However, due to the increased number of cuts per resistor required, the price can increase substantially. This method is recommended for DC applications. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

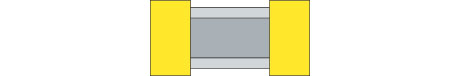

Scan Cut: This method offers both high-accuracy and high-frequency compatibility. The resistor material is typically removed from each edge of the resistor equally. This technique typically requires considerably more time per resistor than the other trim types. It is also more expensive. This method is recommended for all applications. |

|

|||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

For more information on resistor trimming, please request document #DG50020 “Design For Manufacturability,” in PDF format (requires Adobe Reader). |

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||