Thermal Performance of Tantalum Nitride Films*

|

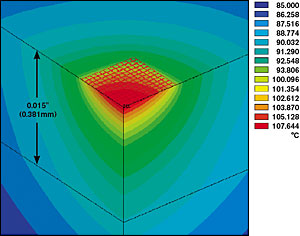

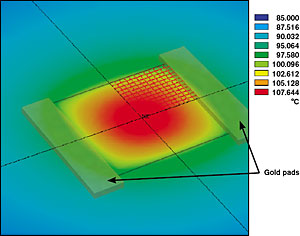

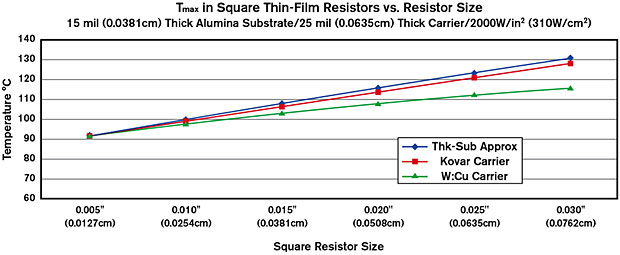

Figure 1 illustrates the temperature distribution for a 15 mil (0.0381cm) square Tantalum Nitride resistor with a power density of 2,000 W/in2 (310W/cm2) and a heatsink temperature of 85°C. The plot shows how heat spreads from the resistor through the 15 mil (0.0381cm) thick Alumina substrate and into the 25 mil (0.0635cm) thick Kovar carrier. Figure 2 shows the surface temperature distribution for the same resistor of Figure 1, again with a power density of 2,000 W/in2 (310W/cm2). Notice that the temperature within the resistor varies from 107.6°C at the center (Tmax) to 96°C at the resistor corners. From accelerated tests, the hottest spot degrades first. Use Tmax to calculate MTTF for a thin-film resistor Figure 3 is a plot of Tmax versus the length of square resistors on a 15 mil thick Alumina substrate. Power density is 2,000 W/in2 (310W/cm2) and the heatsink temperature is 85°C. Two different carrier materials are considered: Kovar and W:Cu. Also shown is the “Thick Substrate” Approximation (The Alumina substrate is made so thick compared with the resistor size that the thermal spreading resistance into the substrate dominates the overall thermal resistance.) |

Several important conclusions about thermal design of thin-film resistors can be drawn from Figure 3: •Imposing an arbitrary cap on the resistor’s power density (W/in2 or W/cm2) is too restrictive. A thermal analysis based on the physics of heat flow is required for a sensible estimate of MTTF (For instance, power density in the 5 mil square resistor could safely be raised to 15,000 W/in2 or 2325 W/cm2). •For fixed power density (W/in2 or W/cm2), smaller resistors have lower Tmax. •When the square resistor length exceeds the substrate thickness, choice of carrier material becomes important. •For the W:Cu carrier, Tmax increases more slowly than linear. •The “Thick Substrate” Approximation may be much too pessimistic for high-power resistors. Please request document #DG50020 “Design For Manufacturability,” in PDF format (requires Adobe Reader). |

Figure 1: Surface temperature distribution through Alumina substrate

Figure 2: Surface temperature distribution across a square resistor |

||||||||

|

* To be used as reference only. Calculations based on square resistors on listed material. Other resistor designs and materials may have different results, such as fused silica/quartz may act as an insulator and may not be recommended for this type of application. Please contact ATP with your requirement and application. |

Figure 3 |

|||||||||